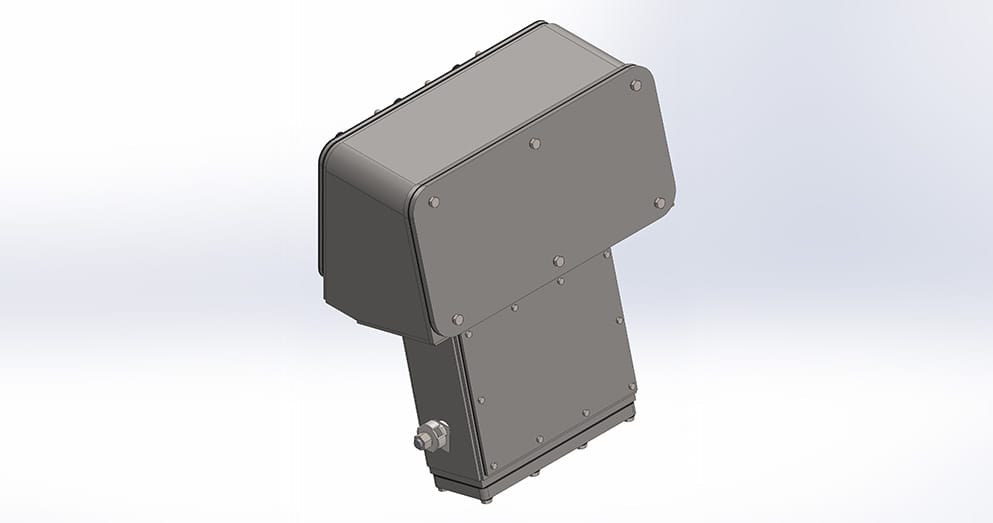

Weatherproof

ATEX certified

Ex nA

Most often supplied as direct replacements for historical GEC manufactured machines previously fitted with the Weatherproof box and suitable for Zone 2 applications.

Technical Description

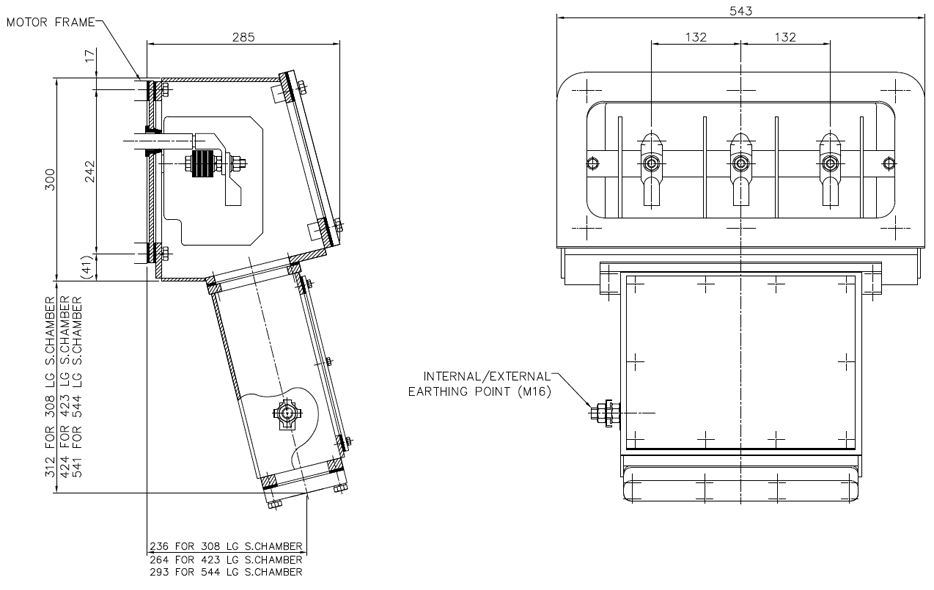

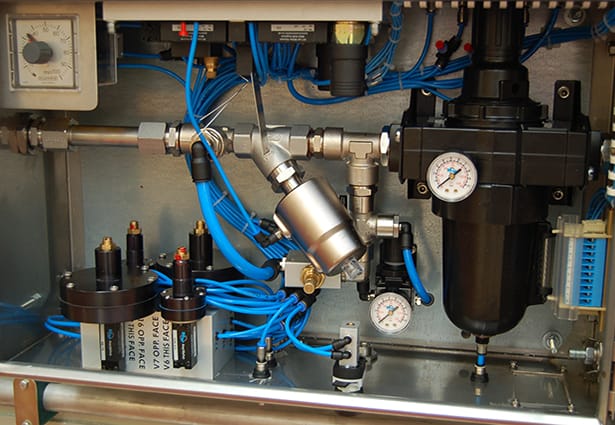

The terminal assembly consists of one insulator bar running across the enclosure with three stud terminals. Each stud terminal consists of an M12 x 80mm screw passing through the insulator bar, secured by a nut and lock washer, with two plain washers to protect the insulator bar. The cable lug from the equipment leads and the incoming leads are then placed over the stud and clamped by a plain washer, nut and lock washer. Between the terminals and outside the two end terminals there are 5 mm thick insulating barriers secured to the terminal bar by a continuous fillet of adhesive around the joint. The terminal bar is secured at either end to pillars that rise up from the base of the enclosure. The enclosure is made from fabricated steel plate. Extra portions of steel are welded under the lid flange so that the lid fixing screws can enter blind holes. A separate plate covers the base of the enclosure with a gasket between the plate and the base and another between the plate and the equipment mounting. The equipment leads come through holes in this plate and are sealed by rubber grommets which can be varied to suit the diameter of the cable insulation. The enclosure is wide but shallow in height and can only be used in conjunction with a cable dividing chamber, which has a gland plate at the base. Depths of dividing chamber are available to meet different cable requirements. There are appropriately marked internal and external earth terminals on one side of the dividing chamber. All joints are sealed with 3 mm thick neoprene bonded cork gaskets.

Spares Support

A full range of spares to support this terminal box assembly are available.