News

Quartzteq’s revolutionary new ‘Rosenberry’ synchronous motor starting hub receives Ex ‘ec’ certification

30 January 2020

Having just had full ATEX and IECEx Ex ‘ec’ certification for its Rosenberry Hub, Quartzteq, part of the Quartzelec group, the independent engineering service provider that’s globally recognised as an expert in rotating electrical machines, can now offer awaiting customers a synchronous motor starting hub that conforms to all the latest standards and can be used in hazardous environments.

"Gaining compliance with the stringent yet essential Health and Safety Requirements now means that we are able to deliver a vital motor starter hub for use in potentially explosive atmospheres,” stated Ian Martin, Design Manager – Special Projects. “The design and flexibility of our Rosenberry hub, along with the split variant developed and launched last year, now that we have attained the important and updated Ex ‘ec’ certification, means that we can offer customers worldwide a viable and cost effective synchronous motor starting hub.”

The Rosenberry Hub can be fitted to new motors or retrofitted to existing machines as part of life extension programmes as it allows a synchronous motor to be started asynchronously without damage even when located in a potentially hazardous environment. The hub is Ex certified for use on S1 or S2 duty cycle machines and is electrically connected to the rotor coil and exciter. A significant change within the new certification is the option to use a keyed shaft variant in addition to the standard cone clamp design, which is an important requirement for several customers.

The stresses created when starting synchronous motors can cause serious equipment damage but for fixed speed synchronous motors that need to start asynchronously, extra switching devices are installed on the rotor to allow the induced field currents to flow safely without damaging components.

The Rosenberry Hub range complements other Quartzteq branded and marketed products that include fault rated and certified terminal boxes, flexible condition monitoring services, electronic and pneumatic purge solutions; available with ATEX and IECEx certification.

About the Rosenberry Hub and its operation

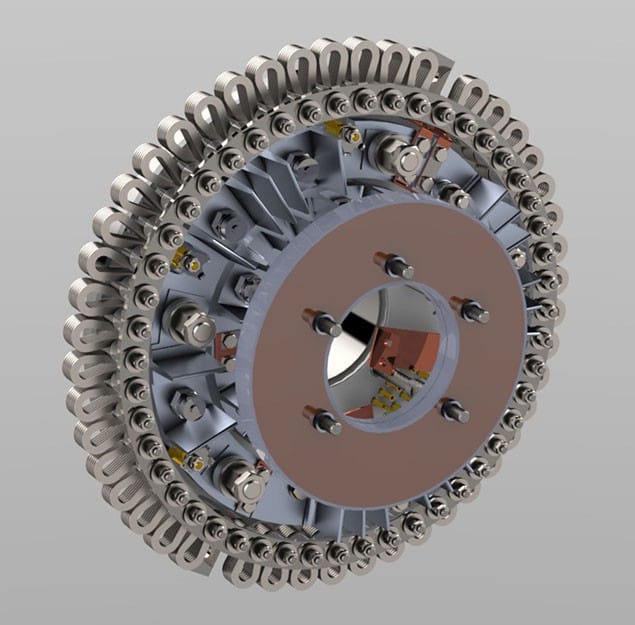

Based on Rosenberry Hub principles first developed in the 1990s, a typical hub weighs in at around 140Kg; and at 345mm in length and 710mm overall diameter it can be fitted on machines with a rotor diameter of 130mm using a cone clamp or a wide variation of keyed shafts. Suitable for rotating speeds of up to 1800rpm, it is designed to run for more than 1,000,000 hours, delivering almost faultless operation throughout the life of the machine. The hub is also exceptionally flexible, being conservatively rated at 600Adc and 750Vdc (1500V PIV) and is appropriate for use on the majority of OEM manufactured synchronous motors.

When starting the motor, the stator supply is energised with no excitation being applied to the exciter field. This means the stator current produces a rotating field that induces an alternating voltage in the motor field which in turn forces the motor to accelerate until it reaches synchronous speed. Motor starting torque during run up is improved by a short term rated starting resistor within the rotor circuit which is switched out once the motor is synchronised to minimise losses.

Developed using devices with high dv/dt withstand, all components are easily accessed and have been specifically selected for rotating duties. Many of the standard silicon devices used are readily available to help minimise costs and provide supply chain security. The hub also features the minimum number of connections and wires to improve reliability. Full maintenance and support is also available from the Quartzelec group for any hub it delivers and full support for any machine can also be incorporated.