News

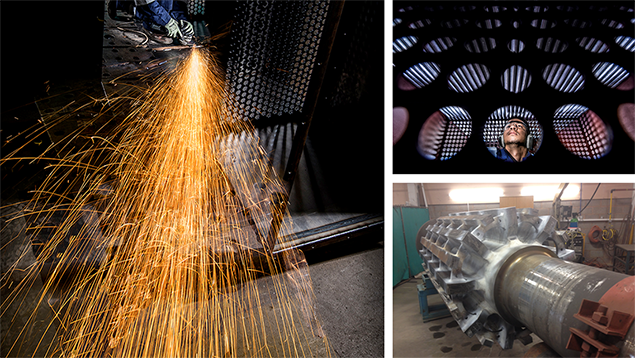

TS Metals complies fully with new HSE directive on welding

19 May 2020

With new legislation relating to mild steel welding having been announced earlier in 2019, TS Metals, part of the Quartzelec group of companies and a welding and fabrication specialist, had previously utilised portable Local Exhaust Ventilation (LEV) equipmentin the welding bays at its Rugby based workshop facilities, but has now completed its investigations and invested in a new permanent state‑of‑the‑art ventilation system, at a cost of over £50k.

“The welfare and safety of our operators is paramount, and all equipment and systems throughout our business fully comply with legislation,” confirmed Ian Addison, Business Unit Manager for TS Metals. "Following the new legal requirements, we worked with the Quartzelec Health & Safety Team to conduct intense investigation into possible ventilation options before new equipment was procured allowing us to install this permanent ventilation solution in the first week of March 2020”.

“Covid-19 restrictions however meant that the electronics could not be connected by the installers and whilst the portable solution we had initially adopted met HSE requirements, we wanted to ensure that our new, fully compliant permanent solution was protecting the health of our workers and site visitors ahead of our next HSE inspection. With extensive engineering support at hand internally, we therefore called upon our skilled team of engineering colleagues at Quartzelec’s Bury St.Edmunds business to push forward on our behalf and fully commission the installation.”

Lorna Smith, TS Metals/Quartzelec’ Health & Safety Advisor added: “It’s now recognised that the mixture of airborne particles/fumes and hot gasses produced by the weld fume process are dangerous to anyone working with them and we needed to ensure such fumes are not inhaled by our operators and are safely captured.”

All welding now must be undertaken with suitable exposure control measures being in place as welding fumes have been found to be carcinogenic and there is no known level of ‘safe’ exposure. Specialist welders must now have appropriate safety procedures in place. The Control of Substances Hazardous to Health (COSHH) Regulations first issued in February 2019 provided new legislation advice on how to control risks to health from welding fumes. The use of alternative cold joining techniques were recommended along with welding in ways that produce less fumes. Local Exhaust Ventilation (LEV), the use of Respiratory Protective Equipment (RPE), and Personal Protective Equipment (PPE), along with maintaining control measures, good general ventilation and providing a better understanding of the risks and use of controls were also referenced in the regulations.