Case studies

Waste Management Service Provider

Project Summary

|

Service: |

New Equipment & Spares Supply |

|

Duration: |

20 Months |

Background

Quartzelec had the opportunity to work with a waste management service provider who are responsible for the disposal, keeping or treatment of waste and the transfer and recycling of waste, including its incineration and conversion to electricity.

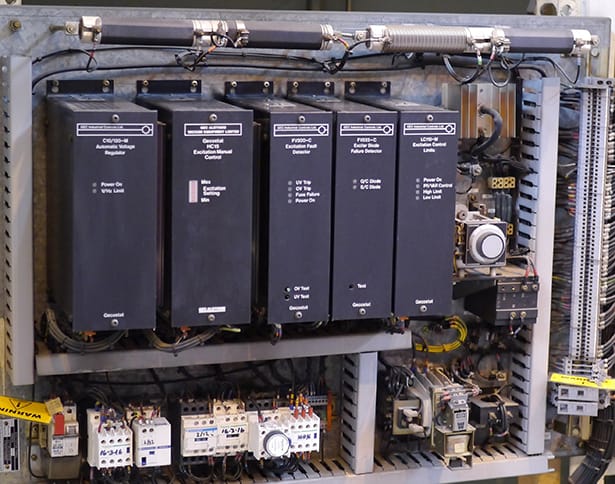

The site was originally fitted with 4 x C10/120 type AVR systems. These are a legacy GEC/Alstom/Converteam/GE systems that the OEM no longer manufactures for stock and minimal support is available in the event of a breakdown.

With limited support and no spares, the client decided to upgrade the excitation system to a modern digital equivalent and called upon Quartzelec.

The Project

Quartzelec designed new back-plates, based on the Basler DECS 250 Digital Excitation Control System, to be mounted and wired in the existing cubicles. To provide additional system security, a dual channel scheme was supplied, enabling a transfer to the Back-up AVR, in the event of a fault with the Main AVR, without interrupting generation.

The new systems were designed, built and tested at our Rugby factory and delivered to site to enable installation and commissioning, by Quartzelec, to take place during customer's planned outages. Fully supplied with a new set of circuit diagrams, technical manuals and training, the client can rely on Quartzelec to provide support at all levels.

In addition, the client has a further generator, the 'House Set', with an associated excitation system, a single channel DECS 200 based scheme. During this upgrade project the 'House Set' developed an AVR failure which we were able to resolve by upgrading to a new DECS 250 module.

Due to our non OEM status, flexibility is just one of our many advantages, enabling Quartzelec to design the system to meet the client's exact requirements. Delighted with the service provided, the client has since purchased spare parts and continues to look to Quartzelec for service and support.

#UnparalleledInEngineeringServices

Follow us on Facebook, X & LinkedIn

CS72